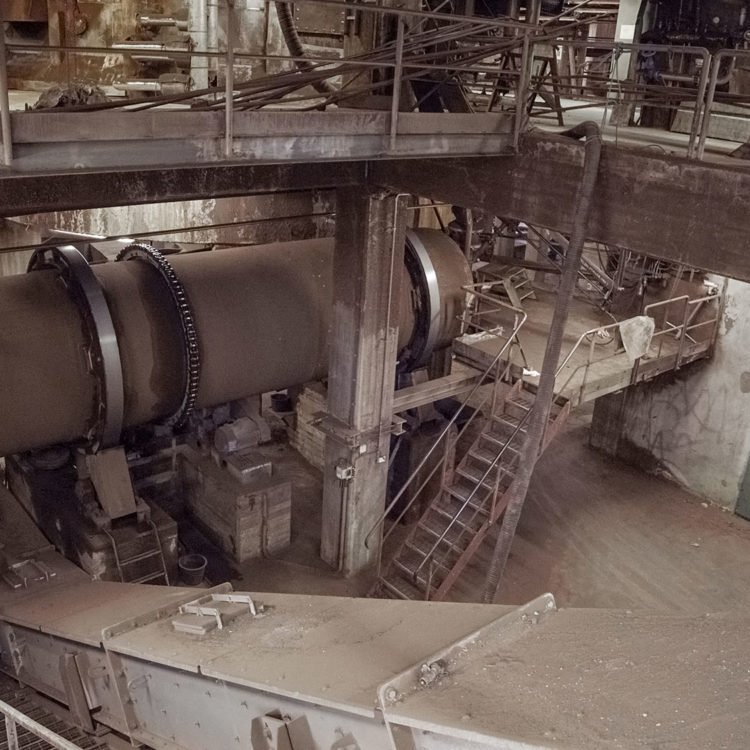

Cooling / Cooling drum

When high cooling power is needed at a high capacity

Kopar cooling drum is an ideal solution when high amount of material needs to be cooled effectively. It is very applicable for cooling of hot and abrasive materials.

Main requirement for a high cooling rate is the free flowing of the material. However, the cooling rate is independent of particle size. Cooling from 900 °C to even 100 °C is possible in one unit, depending on application and capacity.

The cooling capacity of one drum is typically 10-50 t/h and the cooling power 1-5 MW.

Cooling is based on the constant movement of the material inside water-cooled sections, thus efficiently combining heat conduction and, due to proper mixing, heat convection.

Cooling drums can be retrofitted to the existing plant and its auxiliary equipment arrangements.

On the other hand an entire system can be designed completely from scratch to meet the requirements of the new plant.

The drums are designed so that the complete system can be tested at our factory before shipping. This ensures smooth installation and speeds up the commissioning phase of the equipment.

Suitable usage cases for cooling drums

Metallurgical Industry:

Cooling of metallurgical calcine, i.e. zinc calcine or copper calcine after a roasting process

Energy & Power Industry:

Cooling of bottom ash

Typical features of Kopar’s cooling drum are

Capacity

(t/h)

10 – 50

Max. material in (°C)

900

Max. material out (°C)

100

Cooling power

(MW)

1 – 5

Designed to last in the toughest conditions

Exact cooling values

Our calculation models can determine exact cooling values for each customer case individually to find the optimal solution.

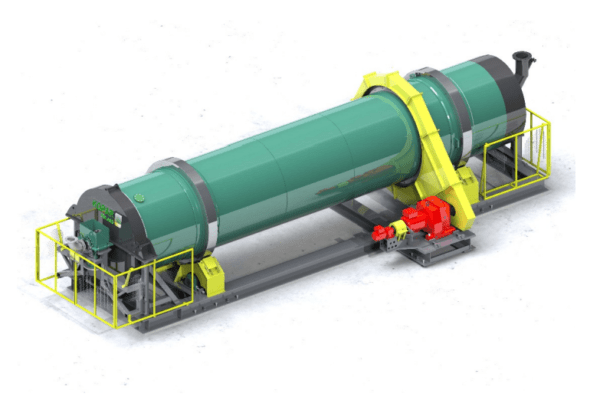

The cooling drum can have a counterflow cooling system with such an internal structure which maximizes the heat transfer surface. These, together with optimally designed mixing lifters inside the cooler, ensure the maximal cooling efficiency.

Trouble-free operation

Durable design with changeable wear parts ensures trouble-free operation. As the system is not pressurized, and thus, not a PED-regulated vessel, the design decreases engineering, operational and maintenance costs.

Operation is dust free while maintaining high production rates, even with a single unit. It can even handle metallurgical dust.

Technical specification

Bulk material is fed to the cooling drum’s feed chamber through a stationary inlet opening. The drum is supported on the rollers and rotated by either roller chain transmission or girth gear, depending on the size of the unit. The drum is slightly inclined for optimum residence time required for set cooling performance.

Test how Kopar cooling solutions fit your production plans

You have a challenge that needs solving?

Let us help! Contact us for more information about our products and services.