Cooling / KRC Rotary Cooler

When you need extreme cooling performance

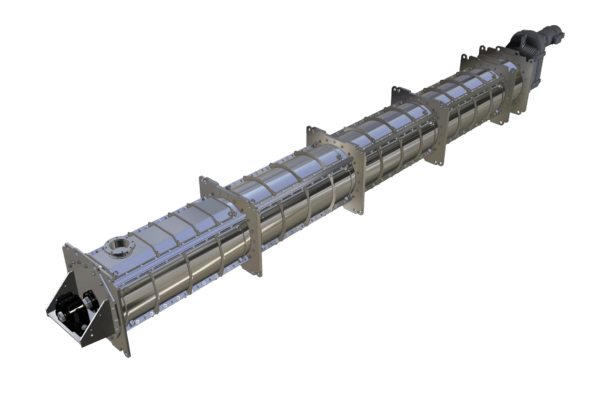

Our rotary cooler’s patented design overcomes traditional cooling screws. New high-capacity and low-wear technology with flexible layout design brings significant cost savings for high-demand cooling applications.

The Kopar KRC-series Rotary Cooler is the latest expansion to our cooling portfolio, which already offers a range of cooling drums, conventional cooling screws and cooled drag chain conveyors on the market.

With its high cooling power, the KRC is best suited for extreme cooling needs. Main design utilizes mixing and retention time in such an optimum way that both heat convection and heat conduction are maximized, however, keeping the wear rate extremely low.

If you need extreme cooling performance, the KRC is the best available solution on the market.

Prime benefits of the KRC coolers are:

- Very high cooling power and capacity per screw

- Very low maintenance costs

(70-90 % lower than in conventional cooling screws) - Flexibility with respect to lay-out

- Modular structure for easy and quick maintenance

If the video above is not visible, watch the video in Youtube

Typical features of KRC cooling screw

Material in (°C)

900

Material out (°C)

50-200

Capacity (t/h)

10

References

52

Actual cooled materials: bottom ash, fly ash, burnt lime dust, activated carbon

Get the best cooling power with our KRC

Efficient cooling for ashes

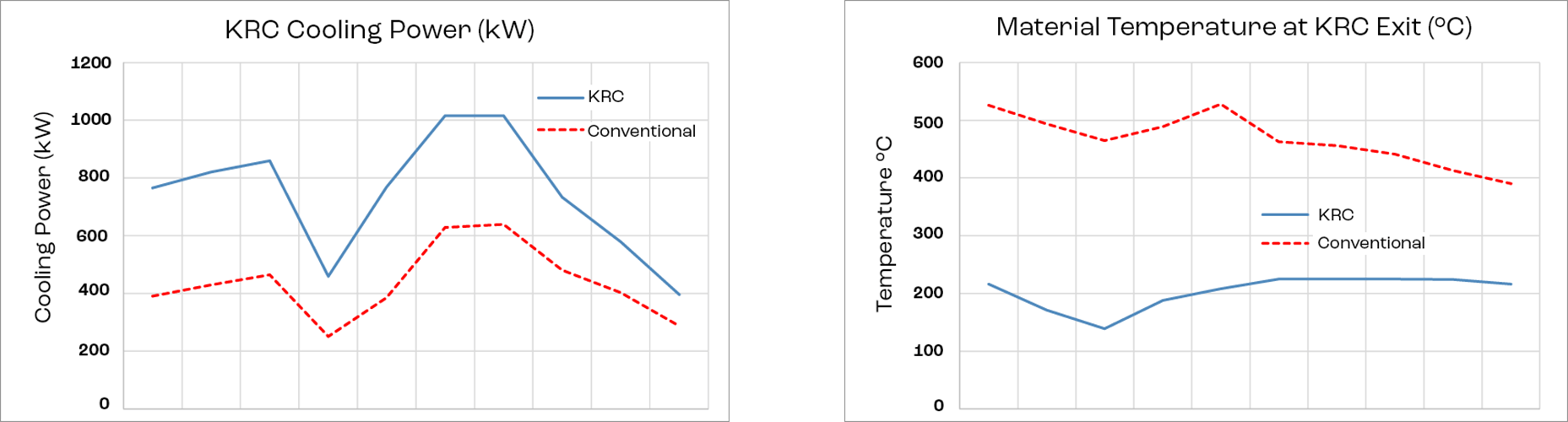

The KRC is the best available solution on the market, for example, for bottom ash. Cooling power can be as high as 1 MW per cooling screw. As a result, the smouldering hot bottom ash can be efficiently cooled from a temperature of 900 °C to around 200 °C even at a high capacity of over 5 t/h. Furthermore, thanks to the high cooling power, fly ash can be easily cooled from a typical 250 °C down to well below 100 °C, de facto, below 50 °C. The range of cooled materials typically includes ashes from incineration processes.

KRC brings considerable savings

One Kopar Rotary Cooler can do the same amount of work as two conventional cooling screws. Therefore, the total CAPEX is lower. However, a significant difference in cost comes with substantially reduced operating expenses and maintenance expenses, which are reduced by more than half. The latest innovations of the KRC have resulted in excellent operational performance by avoiding clogging, fluidization and any other uncontrolled and unfavourable behaviour of the hot ash.

Technical specification

The range of KRC coolers consists of various sizes with typical cooling capacities ranging up to 10 t/h with high material inlets up to 900 °C. Outlet temperature typically varies between 160–250 °C, depending on the production capacity, specific heat capacity, particle size and cooling water parameters.

KRC also reduces the space needed for cooling equipment, therefore you can increase the cooling capacity easily without allocating more space for cooling applications.

Test how Kopar Rotary Cooler fits

your production plans.

You have a challenge that needs solving?

Let us help! Contact us for more information about our products and services.