Solutions / ATEX

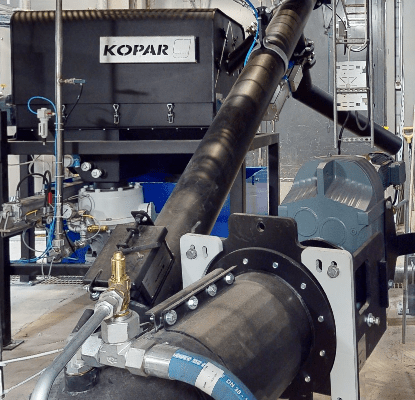

Use of Kopar equipment in ATEX facilities

The ATEX directives apply to equipment used in potentially explosive atmospheres, such as electrical equipment and mechanical equipment with an ignition source.

We manufacture ATEX equipment for equipment categories 1, 2 and 3. Where necessary, we use Eurofins Expert Services Ltd as a notified body.

We have years of experience in various ATEX procedures and we have supplied ATEX-approved equipment such as:

Currently valid ATEX 20/22 certificates can be found for the following Kopar equipment:

Responsibilities in the ATEX procedure

Safety is of paramount importance to us in everything we do. Our solid experience ensures that projects are carried out according to requirements. We comply with safety standards at every stage of work, from design to final site operations. We train our personnel in safety matters regularly and continuously improve our internal security practices.

In order to comply with the specifications of the ATEX Directive, we need comprehensive information from the customer about equipment and processes, including, for example, an explosion protection document. We are responsible for ensuring that the equipment is designed, manufactured, installed and commissioned in accordance with the source data and the requirements of the explosion protection document. If necessary, we will use Eurofins Expert Services Oy to assess the suitability of the product for the intended use.